Brush card locker-Card Introduction

The Brush card locker represents a revolutionary approach to secure storage in public spaces. This innovative Card-swiping locker system combines convenience with advanced security features. Designed for modern environments, the Brush card locker addresses the common challenge of temporary item storage. Users can easily access their belongings with a simple card swipe. The Card-swiping locker technology has transformed how public spaces manage personal items.

Brush card locker Versatile Applications

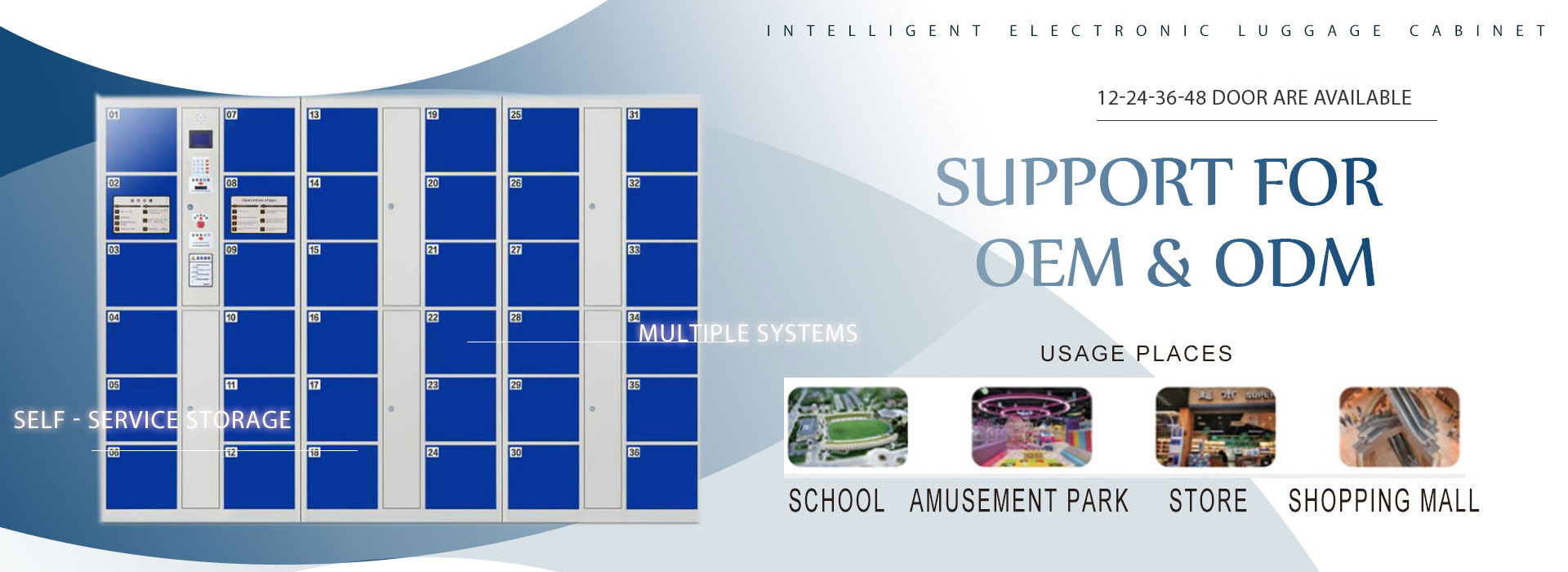

The Brush card locker excels in various public environments with fixed consumer groups. School libraries benefit from Card-swiping locker installations for student backpack storage. Membership supermarkets integrate Brush card locker systems to enhance shopping convenience. Clubs and public libraries utilize Card-swiping locker solutions for visitor personal items. Swimming pools and gymnasiums find Brush card locker essential for securing valuables during activities. The Card-swiping locker adapts seamlessly to each unique environment while maintaining consistent performance.

User-Friendly Operation

Operating the Brush card locker requires minimal effort. Users simply press the “deposit” button to initiate the Card-swiping locker process. The system prompts for card verification. Once the Brush card locker reads the card information, the door automatically opens. After placing items inside, users close the door securely. Retrieving items is equally straightforward with the Card-swiping locker. A simple card swipe unlocks the Brush card locker, providing quick access to stored belongings. This intuitive operation makes the Card-swiping locker accessible to all users.

Advanced Features

The Brush card locker offers multiple configuration options. The Card-swiping locker supports “one-card-one-locker” functionality for personalized access. Users appreciate the mid-process item retrieval capability of the Brush card locker. The Card-swiping locker can integrate with networking systems for enhanced management. Brush card locker technology enables personnel identity verification through data docking. The Card-swiping locker maintains comprehensive data recording and querying capabilities. Remote operation features make the Brush card locker exceptionally convenient for facility managers.

Robust Construction

The Brush card locker features superior build quality. Each Card-swiping locker is constructed from high-quality cold-rolled steel plates. The Brush card locker undergoes carbon dioxide gas-shielded welding for maximum durability. The Card-swiping locker surface receives meticulous treatment including rust removal and phosphating. A final plastic spray coating protects the Brush card locker from environmental factors. The Card-swiping locker doors include longitudinal reinforcement for enhanced impact resistance. This attention to detail makes the Brush card locker exceptionally long-lasting.

Brush card locker Enhanced Security

Security remains paramount in the Brush card locker design. The Card-swiping locker incorporates a 360-degree anti-prying electric lock. Each Brush card locker includes an anti-floppy insertion device for additional protection. The Card-swiping locker prevents unauthorized access through multiple security layers. Brush card locker technology ensures stored items remain secure at all times. The Card-swiping locker system provides peace of mind for both users and facility operators.

Intelligent Management

The Brush card locker functions as a comprehensive small-articles storage system. The Card-swiping locker utilizes an embedded computer for advanced control. Management software enables hierarchical access control for the Brush card locker. The Card-swiping locker allows administrators to specify operating hours easily. Brush card locker systems require no consumables, reducing long-term costs. The Card-swiping locker offers convenient upgrade options to meet evolving needs. This intelligent management approach makes the Brush card locker ideal for modern facilities.

Conclusion

The Brush card locker represents the perfect balance of security, convenience, and durability. This Card-swiping locker solution addresses diverse storage needs across multiple environments. Investing in a Brush card locker system enhances user experience while simplifying management tasks. The Card-swiping locker technology continues to evolve, meeting the demands of modern public spaces. For reliable, secure, and user-friendly storage, the Brush card locker stands as the ultimate solution.